Refinec Oy is a Finnish manufacturer of hydraulic oil coolers that deliver highly efficient cooling solutions for a wide range of hydraulic systems, including gear boxes, power packs, cranes and lifting equipment, hydraulic presses, plastic injection moulding machinery, automotive engine and transmission testing, processing machinery and marine thruster, stabiliser and winch systems.

Product Benefits

- Compact design Saves space. Simplifies installation

- Thermal calculations Provided quickly by our technical experts

- Premium quality Made in Finland, using quality components

- Comprehensive range Suitable for heat loads up to 1600 kW

- Rapid delivery Extensive stockholding for fast response

Marine and Land Options

For land-based installations, standard units are supplied with cast iron end covers. Where sea water is used for cooling, marine specification end covers are fitted.

High Temperature

Standard products are suitable for cooling oil up to 120 °C but our comprehensive range offers units for applications where hydraulic oil is required to run at temperatures up to 200 °C.

Tube Stack Options

Whilst cupronickel is the standard tube material on all units, but titanium tube stacks are also available as options to suit customer requirements.

SAE Flanges

On Refinec GL size hydraulic oil coolers and larger, SAE oil flange connections are provided on the shell side of the unit, whilst the smaller EC, FC and FG models feature BSP connections as standard.

Mining Applications

For deep underground mining applications, where ambient air temperatures are high, Bowman offer a range of oil coolers suitable for use with water pressures up to 35 bar.

Specification Options

Sealing rings are available on some units enabling easy service and maintenance of the cooling tubes without having to drain the hydraulic circuit.

Specification

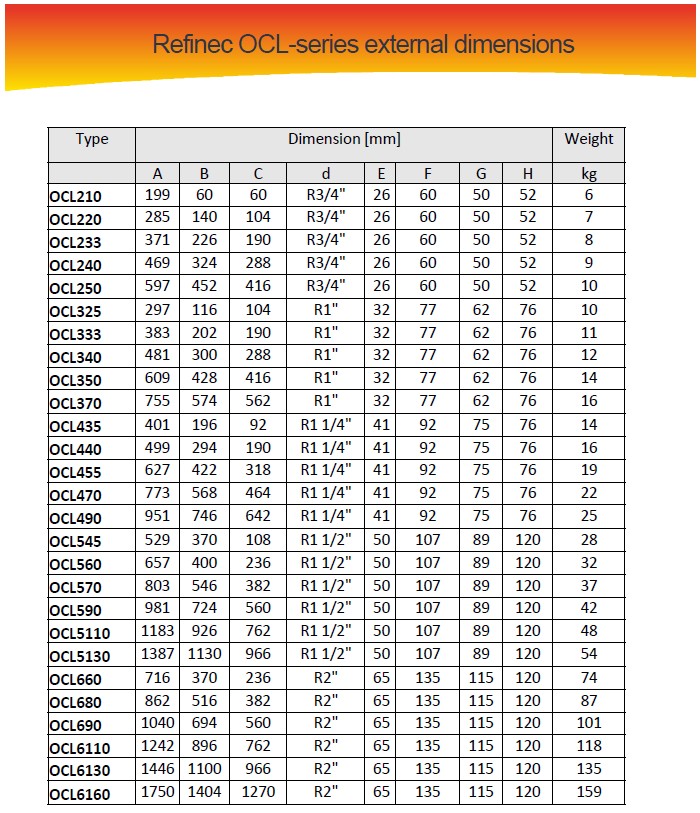

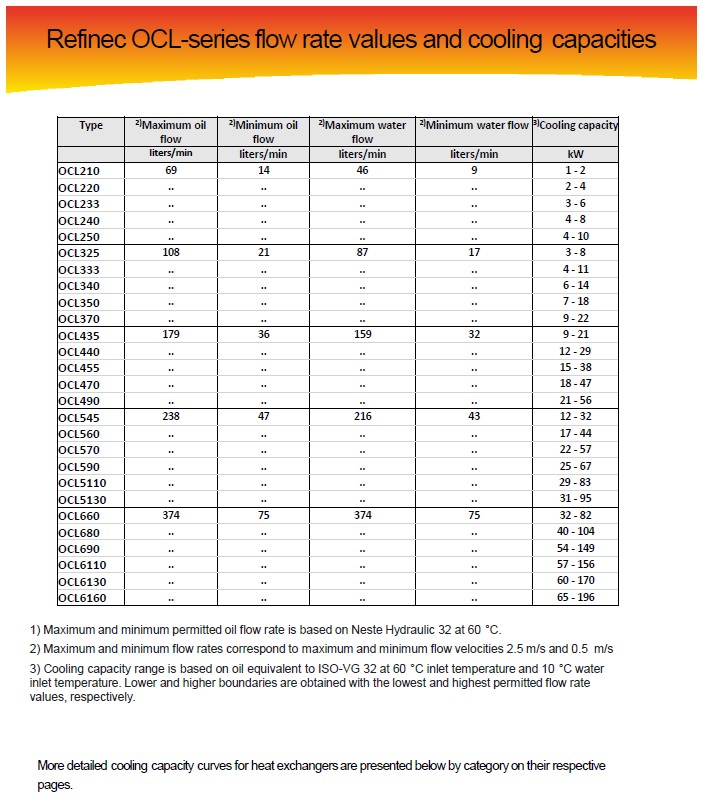

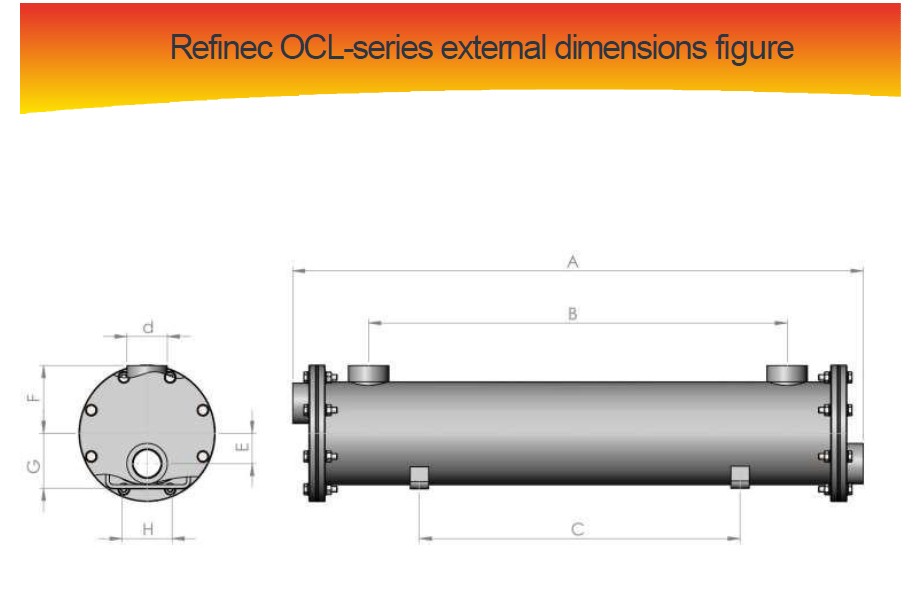

Hydraulic Oil Coolers – Typical Performance and Dimensions

The following information offers a general guide to the performance and dimensions of our standard range of hydraulic oil coolers. For more detailed information on additional configurations and specific applications, please download the product brochure. Computer aided selection software (CAS) is available to accurately select the correct heat exchanger specifically for your application.

Please contact us or your nearest stockist with the following information to receive a CAS selection:

- Oil type (or Viscosity at a specific temperature)

- Oil flow rate

- Required oil outlet temperature

- Heat to be dissipated

- Temperature and source of cooling water

Marine and Land Options

For land-based installations, standard units are supplied with cast iron end covers. Where sea water is used for cooling, marine specification end covers are fitted.

High Temperature

Standard products are suitable for cooling oil up to 120 °C but our comprehensive range offers units for applications where hydraulic oil is required to run at temperatures up to 200 °C.

Tube Stack Options

Whilst cupronickel is the standard tube material on all units, but titanium tube stacks are also available as options to suit customer requirements.

SAE Flanges

On Refinec GL size hydraulic oil coolers and larger, SAE oil flange connections are provided on the shell side of the unit, whilst the smaller EC, FC and FG models feature BSP connections as standard.

Mining Applications

For deep underground mining applications, where ambient air temperatures are high, Bowman offer a range of oil coolers suitable for use with water pressures up to 35 bar.

Specification Options

Sealing rings are available on some units enabling easy service and maintenance of the cooling tubes without having to drain the hydraulic circuit

Specification

Hydraulic Oil Coolers – Typical Performance and Dimensions

The following information offers a general guide to the performance and dimensions of our standard range of hydraulic oil coolers. For more detailed information on additional configurations and specific applications, please download the product brochure. Computer aided selection software (CAS) is available to accurately select the correct heat exchanger specifically for your application.

Please contact us or your nearest stockist with the following information to receive a CAS selection:

- Oil type (or Viscosity at a specific temperature)

- Oil flow rate

- Required oil outlet temperature

- Heat to be dissipated

- Temperature and source of cooling water

WO R K I N G C O N D I T I O N S

Maximum working oil pressure 10 bar

Maximum working water pressure 10 bar

Maximum working oil temperature 100°C

Maximum working water temperature 100°C